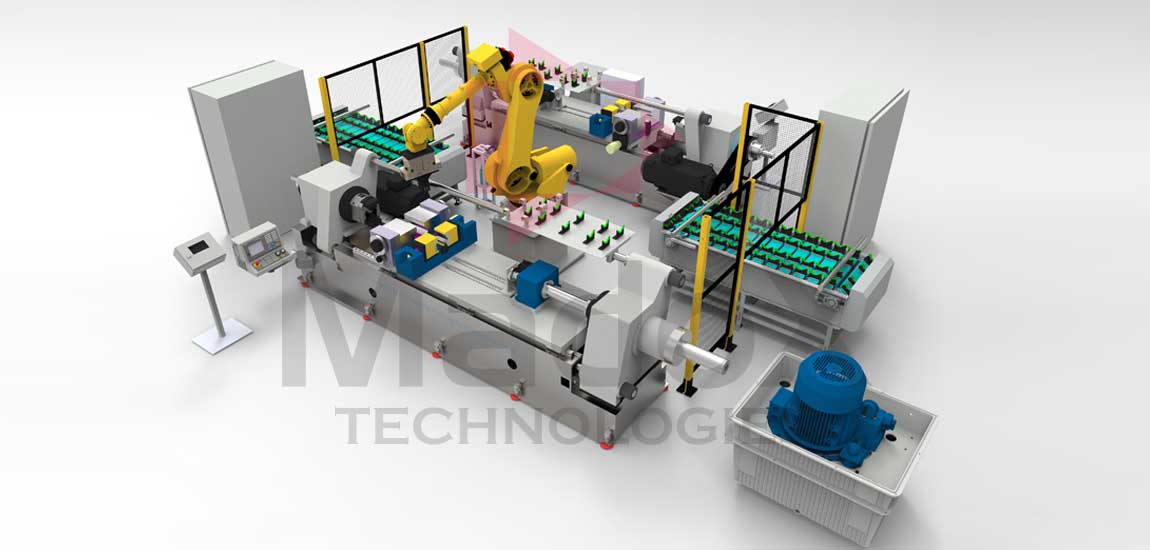

- Input Part Inspection

- Output Part Inspection

- Marking

- Blow Off

- Washing

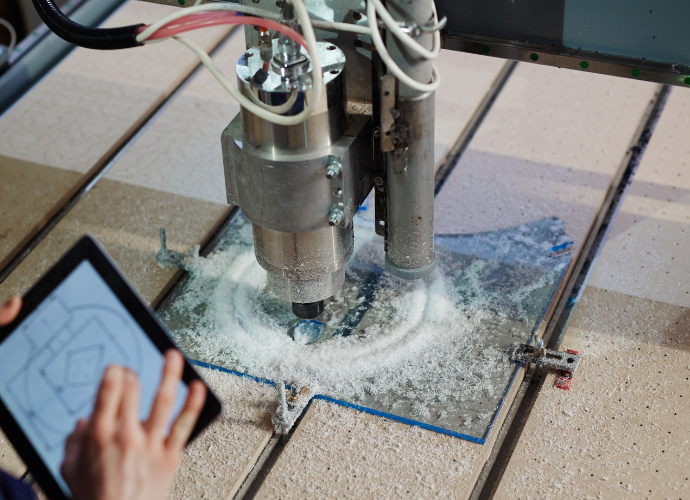

- Deburring

- Sorting

- Packing

- Tending using Collaborative Robot (COBOT)

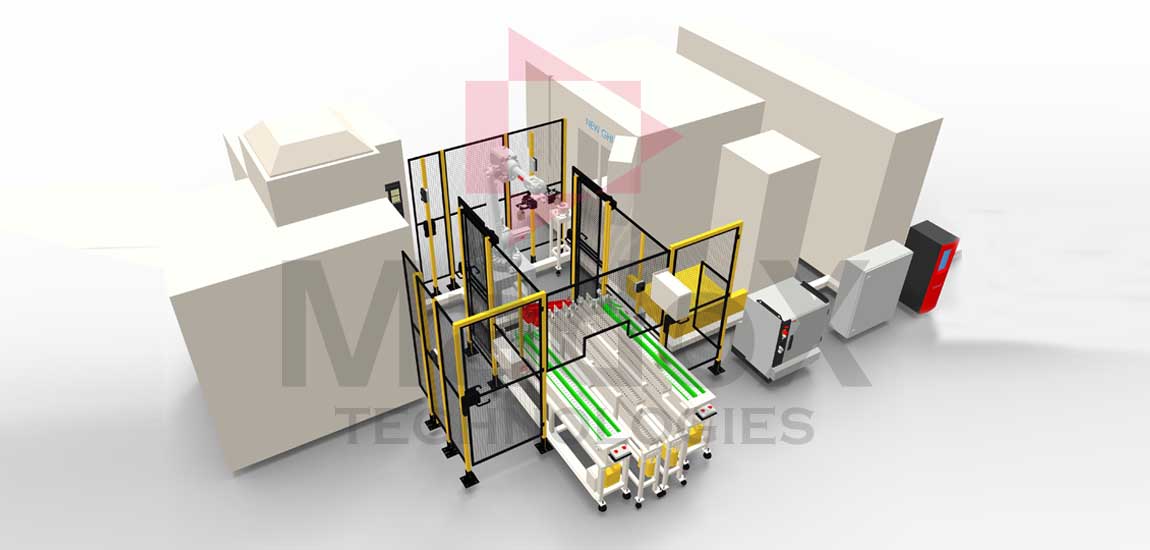

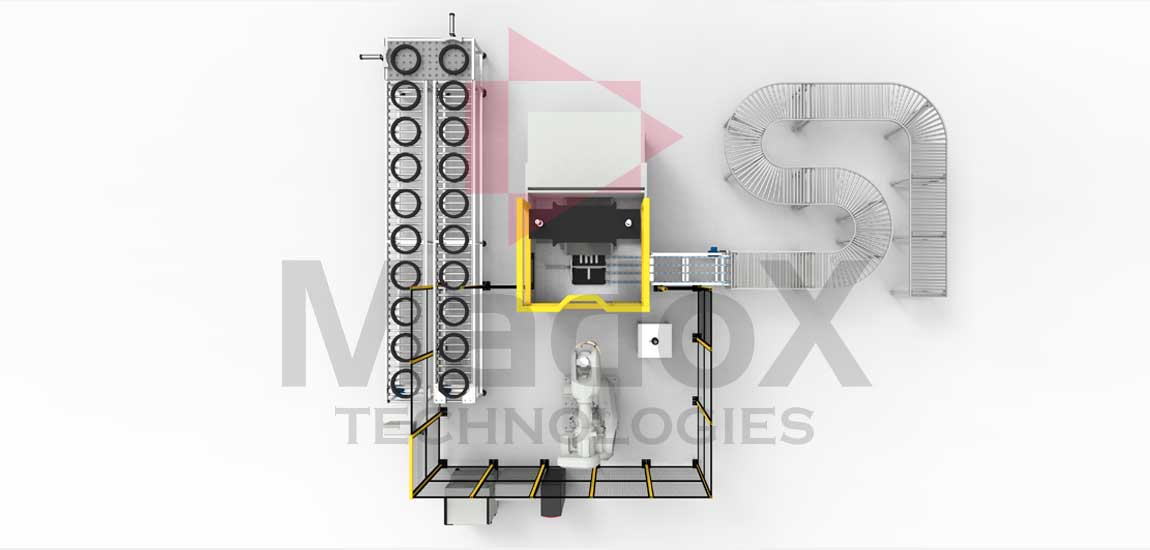

- Loading multiple machines –Solution with Rail or Gantry system

- Injection Molding – Component removal, screw cutting, decorating, labeling, and adding inserts.

- Loading random objects – Vision-based bin picking solutions.

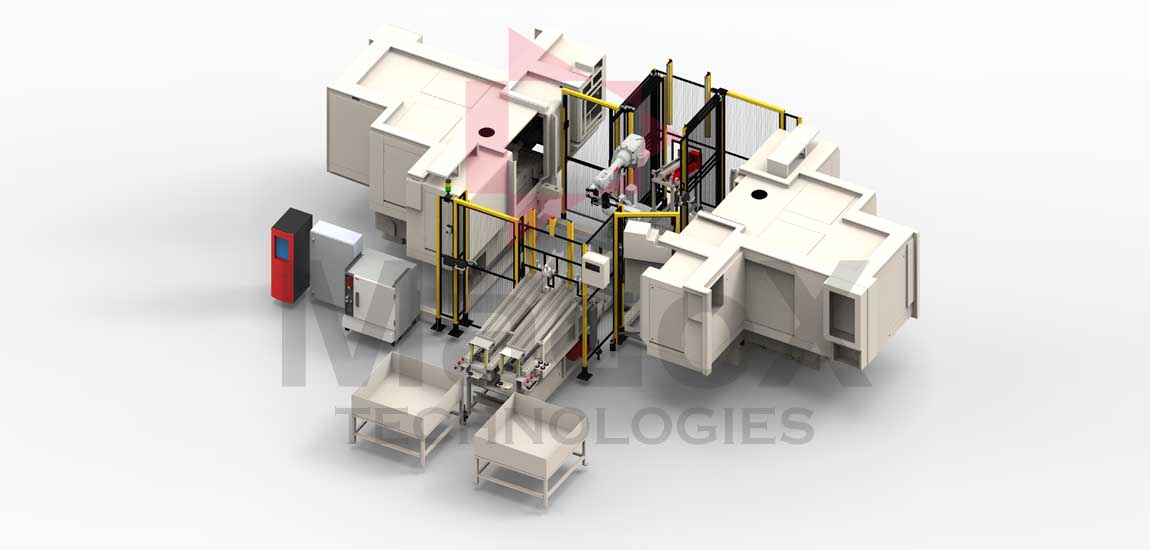

- Press Tending – sheet metal press tending or stamping.

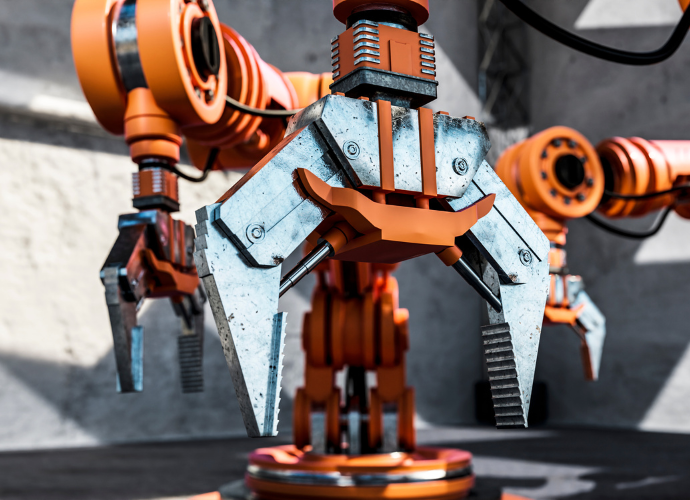

- Forge Tending – loading and unloading, Punching.

- Diecasting – Component removal, Trimming, Coolant spraying

- Holding a product for welding operation

Robotics System integration deals with the design, construction, operation, and application of industrial Robots. Madox designs and integrates innovative and cost-effective robotic solutions for all complicated applications to everyday tasks. We provide Robotic cell solutions with ABB, Fanuc, Yaskawa, Kuka and many other Robot brands available in India. With over a decade and more years of experience in the Robotics Automation Industry, we have designed and installed hundreds of successful Robotic systems across the country for various applications. At Madox Technologies, we begin all projects by carefully understanding our customers’ requirements and asking ourselves how we can help enhance their experience and efficiently integrate a robotic solution into their production. Our experienced in-house team of engineers evaluate the specialized needs of your application, while integrating the latest technologies to work with it. We always assure the quality and reliability of our robotics solutions with innovative designs. Madox, as a turnkey solutions provider, has been successfully helping many of the leading manufactures to reduce operating costs and improve long term sustainability. Our team has a vast experience in handling the below listed Robotics Applications, type of robots, design and manufacture the peripheral equipment.