INNOVATIVE, IMPROVED & UPDATED SOLUTION

Our solutions for you

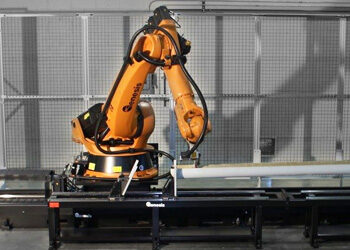

Robotic Solutions

Robotic Welding Machine

Robotic Solutions

Machine Tending Robot

Robotic Solutions

Robotic Material Handling

Control Solutions

Process Control System

Control Solutions

Automatic Control Systems

Control Solutions

Control Panel Solution

Robotic Solutions

Robotic Dispensing Systems

Robotic Solutions

Robot Inspection

FAQ's

Increased safety levels as medications are kept in a sterile environment leading to less contamination

Reduction of dispensing errors without confusion on similar-looking pills.

Maintains counting accuracy

The vendor must be good service provider & provide support and maintenance whenever required.Be Aware Of The Security Risks and take High- Quality Control measures and provide strong network support the automation solution you are choosing must be able to integrate with many network protocols.

Industries like manufacturing, electric power generation, chemical manufacturing, oil refineries, water and wastewater treatment uses automated control system that helps to keep track of all activity, Improve security, minimizes risk and eliminates the hassle of using traditional keys.

Robotic machine tending can increase productivity and improve the working environment. However, demanding safety regulations and expensive vision systems might make investments in the popular application more challenging

- Machine tending reduces the risk of injury

- Provide uptime and accurate repeatability

- Limit Hazardous Environment Exposure For Human Workers.

The automated robotic welding process ensures weld quality due to the electronic weld process controllers. The results are faster, more consistent and better ergonomics for the human workers. Even minor gains in production and quality can have major impact on profitability.

- Consistent Welding Workflows

- Increased Weld Quality and Efficiency

- Conserving Raw Materials.

- Reduced Labor Costs

- Safer Operations

Food and beverage to promote a more sterilized production environment ,health care to enhances clean, quiet, and safe production and distribution companies to automate processes like picking and packing as well as depalletizing,in agriculture help milk cows, plant and monitor crops as well as manage harvests

A solid layout to maintain, and upgrade the system. panel sizing with good space for expansion and efficient heat dissipation.component placement to create component groups with clear logic to their placement. Labeling avoid critical error during servicing.wireway this makes it simple to identify the path and ensures that new wires’ addition doesn’t become a confusing and jumble

Robotic welding automates the welding process to increase accuracy, enhance safety and reduce the time needed to complete each project. These benefits make the robotic welding process a popular alternative to manual metal joining.

Some major issues in robot installation include incorrect programming, hardware malfunctions, and safety hazards. To fix these issues, it is important to have proper training for programming and maintenance, conduct regular maintenance and testing of hardware, and follow safety protocols and regulations to prevent accidents.

A programmable logic controller, PLC, used for automation of typically industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures.